|

Frame1> |

It all starts

with the State Engineer-approved design plans based on code compliance

and the client's chemical storage requirements...

safesafesafesafesafe |

...as determined

by SAFE's no-cost consulting efforts.

safesafesafesafesafe |

|

Frame2> |

Air-tested

secondary containment and wall/roof assembly, third-party inspected. |

|

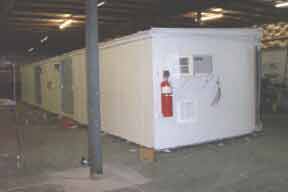

Frame3> |

Fire rating,

insulation, galvannealed interior/exterior, and double module construction. |

|

Frames

4&5> |

Dry chemical

total flood fire suppression and water sprinkler back-up, explosion-proof

appliances and fixtures...

safesafesafesafesafe |

|

...fire-rated

doors, heat sensors, and chemical resistant paint. All stages are third-party

inspected.

safesafesafesafesafe |

|

Frames6&7> |

Loading prep

procedures for transport to the site. |

|

|

Frames8-9-10> |

The SAFE project

team off-loads, places and connects modules, bolts down, and grounds

building.

safesafesafesafesafe |

|

|

|

Frame11> |

Finishing

and QA procedures include: bolt and welds of headers, roof caps, fire

suppression activation...

safesafesafesafesafe |

...grating

install, re-test of electrical appliances,touch-up, and building review

with client's manual.

safesafesafesafesafe |

|

Frames12-13-14> |

The 1,300

square foot interior provides storage for hundreds of 55 gal. drums,

racks for smaller containers, and code-approved aisle space.

safesafesafesafesafe |

The explosion

relief designed panels allow the storage and dispensing of class I-A

flammables.

safesafesafesafesafe |

> > |

> > |

|

Frames

15&16> |

The Factory

Mutual-approved building is third-party State-approved, and SAFE coordinates

the final inspections with the local Building and Fire departments.

safesafesafesafesafe |

|

The client

saved 44% vs design build, and the installation took four days as opposed

to an estimated seven weeks for general construction.

safesafesafesafesafe |

|

safesafesafesafesafe

|

safesafesafesafesafe

|

![]()